Services & Support

Hydraulic & Pneumatic Trainers:

Fluid Power, Hydraulics & Pneumatic’s Training Systems

Advanced Manufacturing offers some of the highest paying and most satisfying career opportunities available today, such as manufacturing operators, maintenance technicians, quality control specialists, scientists, process control engineers, pharmaceutical professionals, and many more. SRIVIN SYSTEMS & ENGINEERS advanced manufacturing program helps students develop the breadth and depth of technical skills they need to excel in technical support roles. Amatrol brings industrial realism to the classroom to teach job relevant skills needed today.

SRIVIN SYSTEMS & ENGINEERS fluid power training systems are the best in the industry. Our learning programs are developed in partnership with industry and education to ensure that the skills are on target to support modern industry needs.

SRIVIN SYSTEMS & ENGINEERS offers a wide array of training systems to meet the many diverse demands in fluid power training. Our learning programs are equally effective for technicians, engineers, production workers and anyone needing further understanding and skills in fluid power systems.

Engineering Services:

SRIVIN SYSTEMS & ENGINEERS offers design assistance to help our customers launch their new products into the market. Customers are encouraged to take advantage of our engineering capabilities early in the product development and design process. Chemical engineering skids are designed as per API 675.

Through the use of Solid-works CAD software, and multiple file sharing options we can work with any client format (Parasolid, STEP, IGES, DXF, DWG). We also have the capability of exporting CAD files direct to our CNC equipment for tool fabrication.

SRIVIN SYSTEMS & ENGINEERS also offers the following engineering support services:

- Finite Element Analysis

- Rapid Prototyping

- Reliability and Durability Testing

- Analysis and Recommendations

Calibration Support:

SRIVIN SYSTEMS & ENGINEERS has been supporting our customers for Calibration of Gauges, flow meters, regulators for Gas, fluid etc.

The instruments are calibrated with state-of-the-art calibration equipment, certified NABL, API, DIN , ASME , ADMERKBLAT standards etc as required national and international standards. Calibration of Instruments used in Fluid power systems as per API / DIN Standards and such as Chemical Injection Skid which are designed as per API 675.

This calibration instruments with certification for gas & Fluid calibrations with unique range of accuracy from 0.001 to 2% as required. Accredited calibrations can be applied to the used and new instruments which shall be replaced time to time ready for commissioning and on site.

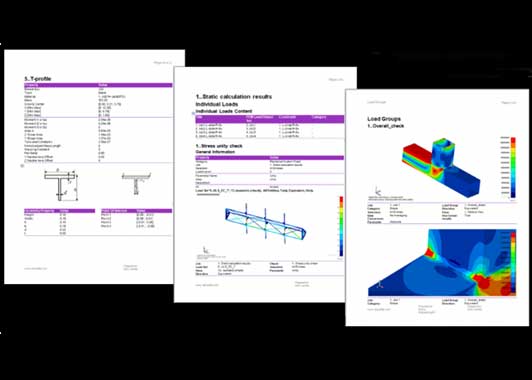

Design Documentation:

The Design Documentation is a leading way of approach towards Project completion. With several years of experience SRIVIN SYSTEMS & ENGINEERS in Design & development our Engineering strength has the capability to understand and support Design Documentation to our esteemed customers.

- Technical design calculation with data sheets

- CAD drawing, 2D & 3D

- Documentation for manufacturing procedures

- Documentation for testing procedures

- Documentation for Installation & commissioning

- Documentation for Operation & maintenance of products

- Documentation for safety procedures

- Documentation for departmental Office procedures

- Deputation of engineers to customers place to understand their design requirement

- Familiar with ISO requirements and processes

Responsibilities:

- Follow SSE with ISO standard, maintain and improve configuration control processes on engineering design.

- Harmonize and streamline documentation processes among product lines.

- Work with related functional groups in SSE to improve material manufacturing and handling process.

- Review and improve if required for any engineering change management process as per project requirement.

- Review/develop necessary procedures and processes to maintain documentation efficiency through puts for both CAD drawings and design related analysis data.

- Managing daily workload of mechanical design and documentation group, arrange resources according to tasks priorities set by project and management team.

- Develop a documentation/process manual.

AMC of Systems SPMS:

Benefits of the Annual Maintenance Contract (AMC)

In today’s competitive era, quality is a prime factor. Quality output from any machine depends on machine’s repeat performance. To get repeat performance; machine maintenance is a key factor. Maintenance of machines with Computerized Numerical Controls requires special skills. Every organisation may not have specialized maintenance team to take care of all variety of machines.

CNC machine manufacturers are the best people to support in maintaining these machines as total technology is available with them. In order to help our customers in getting the best through put from the machine, we have introduced the concept of Annual Maintenance Contracts for the our machines and other machines.

Terms & Conditions.

- Acceptance of AMC depends on condition of the Machine Duration of this agreement will be ONE YEAR w.e.f. date of receiving full earnest.

- The Controllers are expected in good working condition while accepting the contract.

- All recommended tools, instruments, clothe, CTC, lubricants, oils, etc., is in the scope of the customer. In addition, we request the customer to provide basic help to our technician like the material handling equipment, semiskilled labour, etc. else may be charged accordingly.

- The customer is expected to keep available the said machine / s or other facilities. In case of any difficulty the date should be changed in advance by mutual consent. Alternatively the visit will be treated as completed.

- It is possible that machine covered under the plan can breakdown. Our services will in any case be available in such event at an extra cost.

- We can also undertake overhaul/repairs of sub-assemblies / assemblies at an extra cost. In order to ensure minimum downtime the customer is advised to order and stock all the required spares for Preventive Maintenance Contract (PMC) in advance. The list of spares is available on the net for standard models or can be requested. In any case our representative will hand over such list while finalizing the contract.

- In order to get the best results, it is obvious that the customer should carry out the routine maintenance as per the guidelines given in manual. Preventive maintenance shall be carried out as per the laid down format enclosed. However, we will be open to carry out any job over and above the scope of preventive maintenance at an extra cost. We shall be entitled to terminate the agreement in the event of change of ownership or location of the said machine.

- Either party shall entitled to terminate the agreement at any time giving one month’s advance notice, and the customer shall be entitled to refund of the advance on pro-rata basis for the unexpired period of the agreement.

- If prior to offering the machine for PMC the machine is offered for overhauling, a lump sum quotation towards service charges will be offered with concessional service charges as above.

- If there is any breakdown visit in between 2 AMC visits, the same can be adjusted in the total number of AMC visits or, if desired, can be charged extra.

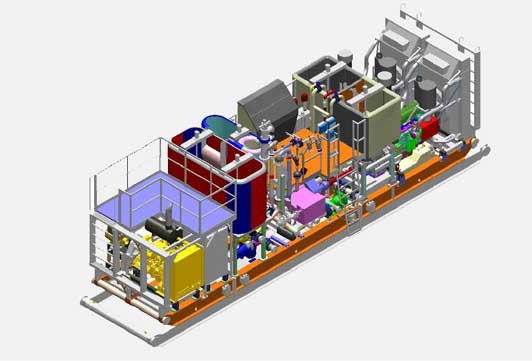

3D Modeling:

SRIVIN SYSTEMS & ENGINEERS has got vast experience in Design, Developing processing system even an entire plant, Special purpose machines, Test rig, Hydraulic & pneumatic systems for industries, Oil & Gas units, power generation sectors and manufacturing is more challenging than ever. Competition is stiff and capital is tight. So the need to control costs, ensure quality, and speed up delivery is critical Hence 3D modeling design services will get through for your success.

SRIVIN SYSTEMS & ENGINEERS Product development solutions can give you a full range of Design, modeling, simulation, and communication tools to create detailed 3D models and drawings for mechanical equipment and systems, General assembly layouts, Process layouts, and electrical, conduit and piping systems etc. You can complete the process and plant design projects quickly, reliably, and affordably.

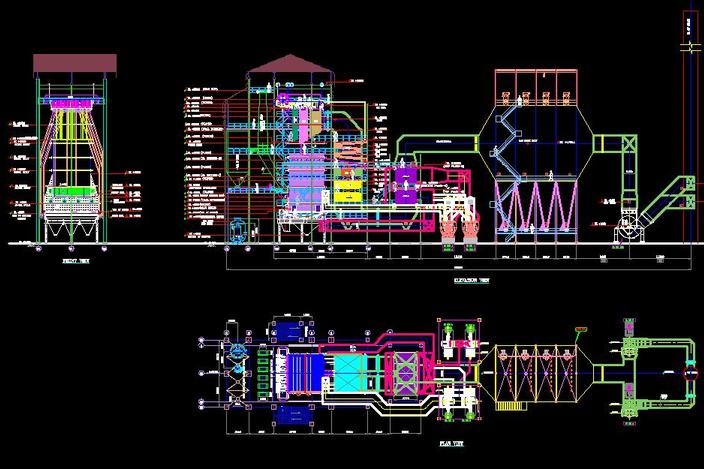

2D Drawing & Design:

SRIVIN SYSTEMS & ENGINEERS has got vast experience in Design, Developing processing system even an entire plant, Special purpose machines, Test rig, Hydraulic & pneumatic systems for industries, Oil & Gas units, power generation sectors and manufacturing is more challenging than ever. Competition is stiff and capital is tight. So the need to control costs, ensure quality, and speed up delivery is critical Hence 3D modeling design services will get through for your success.

SRIVIN SYSTEMS & ENGINEERS Product development solutions can give you a full range of Design, modeling, simulation, and communication tools to create detailed 3D models and drawings for mechanical equipment and systems, General assembly layouts, Process layouts, and electrical, conduit and piping systems etc. You can complete the process and plant design projects quickly, reliably, and affordably.

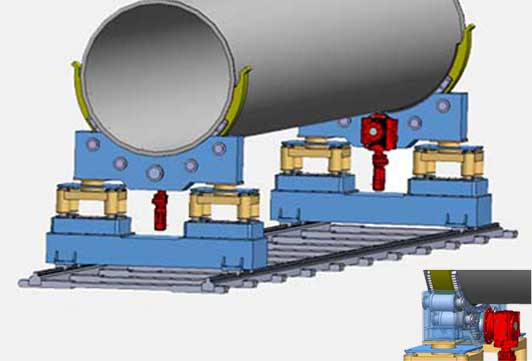

Design of Fluid Power Systems & Components:

Over the last 30 years of experience SRIVIN SYSTEMS & ENGINEERS has provided hundreds of efficient, reliable standard and custom Hydraulic & pneumatic’s units to industries and markets all over the country and aboard. SRIVIN SYSTEMS & ENGINEERS components built with quality under stringent manufacturing standards, the Systems and components are available with options for capacities, controls, P &I piping and valve manifolds, pumping, testing etc with wide range of configurations for customer needs. We at SRIVIN SYSTEMS & ENGINEERS ensure reliable, cost-effective operation and maximum productivity in applications from process manufacturing to alternative energy.

SRIVIN SYSTEMS & ENGINEERS and its Group of companies is available to help customers design customized systems which can deliver flexible, fast, integrated solutions for use anywhere in the world and for almost any industry.

Design of Structures:

Structure are basic load carrying PARTS. Structure is designed for nil deflection considering factor of safety as per requirement when a Hydraulic machine or machine structure is subjected to cyclic repeated loading and unloading. In technically structures are designed such that to keep nominal maximum stress values are less than the ultimate tensile stress limit, and may be below the yield stress limit of the material.

SRIVIN SYSTEMS & ENGINEERS has the capability to understand the proper application and designs analysis it helps you to appreciate the following:

- Whether the component will break and the reason of breakdown

- Is it a fatigue or a fracture response

- Is the design prone to low cycle fracture or high cycle fatigue

- What are the safe operating limits

- What is the rate of crack growth

- How to eliminate fracture problem

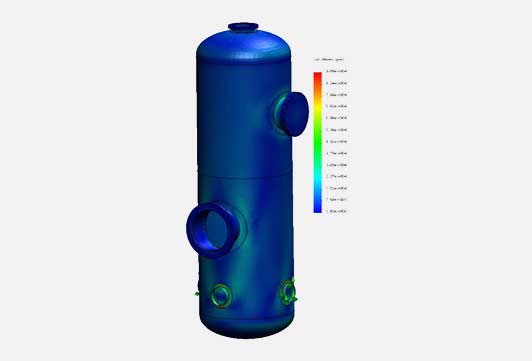

Finite Element Analysis (FEA):

Since the majority of industrial components are made of metal, most FEA calculations involve metallic components. The analysis of metal components can be carried out by either linear or nonlinear stress analysis. Which analysis approach you use depends upon how far you want to push the design:

- If you want to ensure the geometry remains in the linear elastic range (that is, once the load is removed, the component returns to its original shape), then linear stress analysis may be applied, as long as the rotations and displacements are small relative to the geometry. For such an analysis, factor of safety (FoS) is a common design goal.

- Evaluating the effects of post-yield load cycling on the geometry, a nonlinear stress analysis should be carried out. In this case, the impact of strain hardening on the residual stresses and permanent set (deformation) is of most interestThe analysis of nonmetallic components (such as, plastic or rubber parts) should be carried out using nonlinear stress analysis methods, due to their complex load deformation relationship. SOLIDWORKS Simulation uses FEA methods to calculate the displacements and stresses in your product due to operational loads such as:

- Forces

- Pressures

- Accelerations

- Temperatures

- Contact between components

Calculation / Documentation as per Standards:

SRIVIN SYSTEMS & ENGINEERS has good experience with practical experience and so Calculation. How much power is required for a good machine to work economically without any overloads or losses this observation is from grass rood level of observation and understanding what it requires as prime factor. On required projects we consider and contribute the calculations support for the better concept of designs and development.